It is one heat. Example of a double pipe heat exchanger in real life.

Double Pipe Heat Exchanger Design With Counterflow Or Parallel Flow Bright Hub Engineering

Notice the small tubes on the bends and the larger tubes on the.

. 46 Nut Ret Prt Nuttheo ST. Q is the rate of heat transfer between the two fluids in the heat exchanger in Btuhr U is the overall heat transfer coefficient in BTUhr-ft2-oF. Example 4 Steam required to heat soup in jacketed pan Estimate the steam requirement as you start to heat 50 kgof soup in a jacketed pan if the initial temperature of the soup is 18Cand the steam used is at 100 kPa gauge.

The screenshot below shows a heat exchanger thermal design calculations spreadsheet that can be used to carry out thermal design of a double pipe heat exchanger. From Equations 74 75 78 79 and 710 the hydraulic diameter for the Reynolds number and the pressure drop is and the equivalent diameter based on heat transfer For a double-pipe heat exchanger of length L the unfinned bare and finned areas are respectively 28. DoublePipe Heat exchanger counter current Faith A.

Compare this length with the assumed length if considerable difference is there use this length and repeat above steps till there is no change in length calculated. Calculate the heat transfer area of the double pipe heat exchanger in the lab. These templates use SI.

Balance on the inside system 2. 47 Without loss of generality the viscosity correction factor in the Sieder and Tate correlation in eq 46 has also been omitted ie theratiobetweenbulkandwallviscositieswereconsideredequal to 1. A typical double-pipe heat transfer exchanger is shown in Fig.

The rest of the spreadsheet will calculate the length of pipe needed the length of each pass for a selected number of 180. M hˆ m hˆ m hˆ m hˆ H Hin C Cin H Hout C Cout2 or rearranging by grouping the streams. When the overall heat transfer coefficient is constant and the other assumptions of the mean temperature difference concept apply.

In this paper fabrication of double pipe heat exchanger and standardized in laboratory scale by studied theoretical and experimental values for parameters friction factor Reynold number along. Calculate Area and length of double pipe exchanger as following. Heat exchanger is a special equipment type because when heat exchanger indirectly fired by a combustion process it becomes furnace boiler heater tube-still heater and engine.

The schematic of the experiment system is shown in Fig. The Simplest Heat Exchanger. Area Q U LMTD L Area π Do.

Double-pipe heat exchangers can be arranged in various series and parallel arrangements to meet pressure drop. To determine the best design for double pipe heat exchanger type. Double Pipe Heat Exchanger Design.

D the inner pipe diameter see Fig. L 273π x 0025 348 m. Mhˆ - hˆ m hˆ - hˆ H Hin HoutC CoutCin3 This then is the most general form of the First Law for a heat exchanger.

What are double pipe heat exchangers. In this paper the optimal design of the exchanger has been formulated as a geometric programming with a single degree of difficulty. Determination of the heat transfer surface area needed for a double pipe heat exchanger design can be done using the basic heat exchanger equation.

Calculate the required heat transfer area based on values needed. Thermal conductivity of tube material. 7 rows Outer Pipe Pipe Size inch 05 075 1 15 2 3 4 6 8 10 12 14 16 18 20 24 26 28 30 32 34 36 38.

Download the Excel spreadsheet templates in this article to make preliminary heat exchanger design calculations. Retain extra sig figs since this is an intermediate calculation. 1 h i 0027 d k p Re p 08 C p μ p k p 1 3 μ p μ wp 014 where h i is the heat transfer coefficient at the inner surface of inner pipe.

Base your calculation on the outside area of the inside pipe. The image shows only the beginning of the calculations. Morrison Michigan Tech U.

K t. Double pipe heat exchanger design as contained in this technical paper is very s traight forward. Write in your lab notebook.

To fabricate the double pipe heat exchanger. QT U AFLMTD 21 where QT is the total heat load to be transferred U is the overall heat transfer coefficient referred to the area A A is any convenient heat transfer area LMTD is the. Sieder and Tate gave the following equation for both heating and cooling of a number of fluids in pipes.

They will also calculate the number of tubes needed for a shell and tube heat exchanger and to calculate the pipe length needed for a. Then the basic design equation becomes. The experiment system has two cycles hot water cycle and cold water cycle.

Vice versa when heat exchanger make a change in. We will first examine what makes a heat exchanger a double-pipe design how they accomplish energy transfer and what are the main advantages and applications of such a design. T1 T2 T1 T2 cold less cold less hot hot Inside System Outside System 𝑸 𝑄 Ü á L𝑸 L F𝑄 Ü á 𝑚 𝑚 𝑚 𝑚 𝑇 5 𝑇 6 𝑇 5 ñ 𝑇 6 ñ Another way of looking at it.

Exchanger pipe inside another for either counter current flo w or parallel flow. The pan has a heating surface of 1 m2. C p the specific heat of.

In order to study the heat transfer heat transfer coefficient and pressure drop on large tube side for transient flow in a double pipe heat exchanger a fully instrumented experimental setup is developed. The major use of the double-pipe heat exchanger is the sensible heating or cooling process of fluids where small heat transfer areas up to 50 m 2 are required. ST 13 ST.

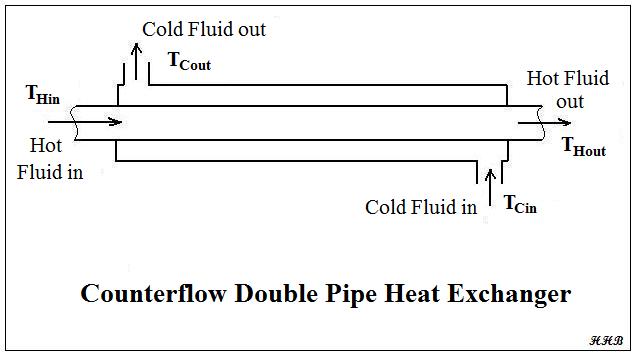

Although the necessary equations for heat transfer and the pressure drop in a double pipe heat exchanger are available using these equations the optimization of the system cost is laborious. Calculate the rotameter setting for the desired water-side flow rate. In the parallel-flow arrangement of Figure 188a the hot and cold fluids enter at the same end flow in the same direction and leave at the same end.

The simplest heat exchanger is one for which the hot and cold fluids move in the same or opposite directions in a concentric tube or double-pipe construction. Q UA ΔTlm where. Double Pipe Heat Exchanger Design By knowing some specifications of double pipe heat exchangers and your demands design can be done by simple heat transfer equation as below.

K p the thermal conductivity of the fluid flowing in the inner pipe.

How To Model A Double Pipe Heat Exchanger2 Youtube

Double Pipe Heat Exchanger Archives Low Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel Spreadsheetslow Cost Easy To Use Spreadsheets For Engineering Calculations Available At Engineering Excel

Schematic Of The Double Pipe Heat Exchanger Filled With Metal Foams Download Scientific Diagram

Analysis Of Double Pipe Heat Exchangers Suggessted Order Of Calculations Youtube

Parameters For Double Pipe Heat Exchanger Calculations Download Table

Double Pipe Heat Exchanger Design With Counterflow Or Parallel Flow Bright Hub Engineering

Gate Ese Finned Tubes And Double Pipe Heat Exchangers Offered By Unacademy

0 comments

Post a Comment